My name is Dan Brubaker Horst and I am a BAR. I reconnected with rocketry in 2020 after leaving the hobby in the early 2000s. My first rocket was an Estes Bull Pup I saw at Walmart as a seventh-grader in 1995. I was introduced to High Power Rocketry the next year by Kurt Cripe, a friend’s dad. My first HPR launch was in Three Oaks, MI in the fall of 1996. My dad, Ken Horst, and I dove deep into rocketry after that.

The basement workshop of my parent’s home was christened “The Rocket Lab” and it was outfitted with progressively larger power tools so that we could fabricate more sophisticated rockets. Over the next 8 years, I spent countless hours in the shop learning and practicing how to build rockets that could withstand the forces of high-power flight and recovery. I fabricated dozens upon dozens of components–fins, bulkheads, centering rings, pistons, “sleds” for electronics, etc.–from balsa, aircraft-grade plywood, and G-10 fiberglass sheeting accented with aluminum, cork, cherry wood, all-thread, t-nuts, polystyrene, and stainless steel fittings. I used a lathe to turn many a nose cone from poplar and, occasionally, basswood. I learned how to use different viscosities and formulations of cyanoacrylate (super glue) and epoxy to make bonds and reinforce surfaces. I used fiberglass, Kevlar, and carbon fiber to strengthen airframes, laminate fins, and reinforce joints. I got quite good at filling wood grain, smoothing surfaces, and using spray paint.

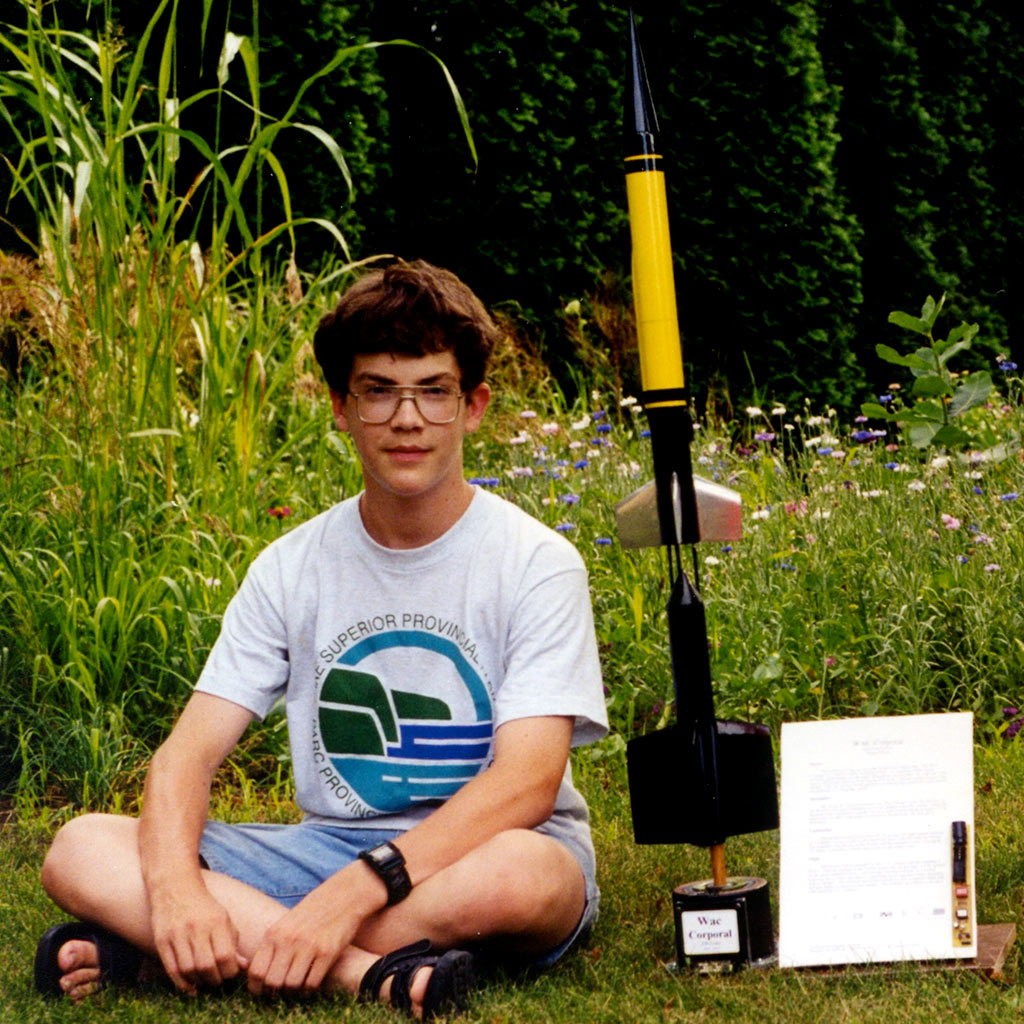

In the fall of 1997, I discovered the rocketry competition at the Elkhart County 4-H fair, one of the largest county fairs in the nation, and said to myself “I could do better than that” after looking at my competition. For the next four years, every year I was eligible to compete, my rocket was selected for the state fair. I still have two of my entries: a scratch-built 3” Ares (4×29mm), and a scratch-built 2-stage BT-60 WAC Corporal (3×18mm to 24mm). Neither one of them has flown but they were designed and built so that they could.

My dad and I started using avionics early on in our HPR models. We tried many different altimeters but used the BlackSky AltAcc the most. My personal favorite was the AED R-DAS which was the same form factor as the AltAcc but gathered more data and had a serial bus to attach additional sensors. (Both Blacksky and AED are no longer in business.) I scratch-built at least a half dozen dual-deployment rockets trying out different arrangements for recovery bays, power management, pyrotechnic charges, arming switches, and recovery harnesses.

By 2001, we were ready to do something more sophisticated with electronic payloads. My dad started the Goshen Radios Aloft Group (G-RAG) where we enlisted several HAM radio enthusiasts to help develop a real-time GPS telemetry package that used packet radio over the 2-meter HAM radio band. Our final project was featured in the January/February issue of Sport Rocketry in 2002. The 3-inch launch vehicle I built for that project flew different payload configurations for several years starting in 2001. The rocket was retired after losing a fin to a hard landing in the Nevada desert at LDRS 26 (2007).

My dad was a physics teacher at Goshen High School and coached at least one team for The American Rocketry Challenge from its inaugural year in 2002 until he retired in 2012. Several of his teams made it to nationals. I missed the age cutoff to participate as a team member (only by a year!) so I served as an assistant coach for a few teams instead. I helped with web content, built a reference launch vehicle, and helped out where I could. One of the Goshen High School teams was selected to participate in NASA Student Launch after placing well and I played an assisting role in that project too.

My last rocketry endeavors before the long break were:

- Overseer: A 4-inch diameter dual-altimeter, dual-deploy rocket I used to certify TRA Level 2 at LDRS 21 in Wayside, TX (2002)

- Optimistic: A 54mm minimum-diameter Dynacom filament-wound fiberglass rocket I flew to 8300 feet at LDRS 23 in Geneseo, NY (2004)