This project is ongoing. See the Notion project page for working notes.

Most hobby rockets have fins made out of flat material–balsa, basswood, birch plywood, G10, carbon plate, etc.–with the edges either rounded or beveled. I think we can do better. For this rocket, I will shape the fins of this rockets using a real NACA airfoil profile (or something as close as I can approximate). These “tiny wings” will be able to generate more lift than their flat-finned counterparts when the rocket needs to make aerodynamic adjustments in flight–encountering winds aloft, leaving the launch rail, etc.–which should result in a more stable, more efficient flight profile.

Design Criteria

- Design for subsonic flights

- Reach an easily-recoverable altitude–under 3000 feet–on a small H motor for an HPR Level 1 certification flight

- Be able to fly well on small, HAZMAT-free reloads from Loki Research

- Be able to fly well on long-burn I motors like the AeroTech I59

- Have a payload bay that can accommodate a variety of video payloads

- Serve as a test-bed for trying new (to me) adhesives and composite materials

- Be as light as I can make it while being strong enough and durable enough for many flights

- Be large enough in diameter that I can test a variety of recovery equipment

- Have parts that would be good candidates for laser cutting

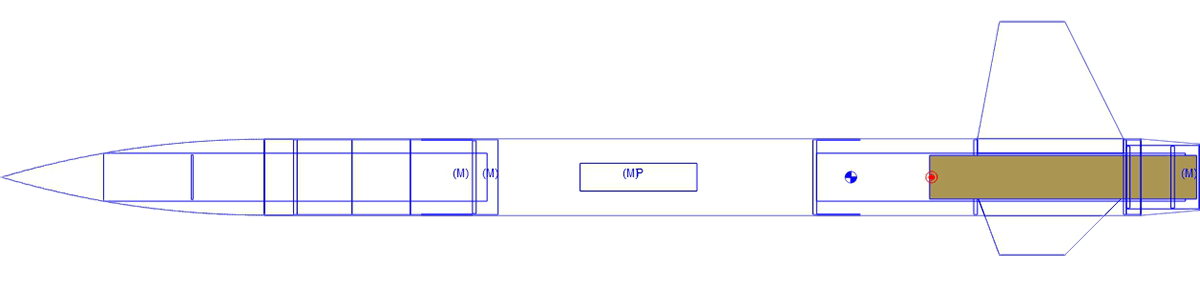

My preliminary design for the aerostructure is:

- Use a BT-80 equivalent airframe (LOC 2.56”)

- Have a 38mm motor mount

- Favor light materials: thin styrene, cardboard, skeletonized birch plywood

- Reinforce with lightweight fiberglass lamination and expandable urethane foam